Revolutionary method of optical power measurement

Lasers of all types and intensities are everywhere, from Pointers for eye surgery to beams of light to metals used to cut clothing fabrics and many products. They are used in printers, data storage and optical communications; Manufacturing applications such as welding; Military weapons and ranging; Medical equipment; There are many other applications. The more important the role played by the laser, the more urgent is the need to precisely calibrate its power output.

Traditional techniques for measuring laser power require a device that can absorb all the energy in the beam as heat. By measuring the temperature change, the researchers can calculate the power of the laser.

But until now, there has been no way to accurately measure laser power in real time during manufacturing, for example, when a laser cuts or melts an object. Without this information, some manufacturers may have to spend more time and money evaluating whether their parts meet manufacturing specifications after production.

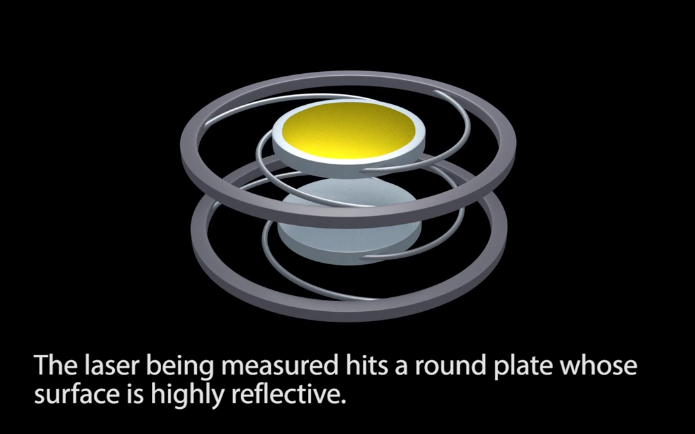

Radiation pressure solves this problem. Light has no mass, but it has momentum, which gives it a force when it hits an object. The force of a 1 kilowatt (kW) laser beam is small, but noticeable – about the weight of a grain of sand. Researchers have pioneered a revolutionary technique to measure large and small amounts of light power by detecting the radiation pressure exerted by light on a mirror. Radiation manometer (RPPM) is designed for high-power light sources using a high-precision laboratory balance with mirrors capable of reflecting 99.999% of the light. As the laser beam bounces off the mirror, the balance records the pressure it exerts. The force measurement is then converted into a power measurement.

The higher the power of the laser beam, the greater the displacement of the reflector. By precisely detecting the amount of this displacement, scientists can sensitively measure the power of the beam. The stress involved can be very minimal. A super-strong beam of 100 kilowatts exerts a force in the range of 68 milligrams. Accurate measurement of radiation pressure at much lower power requires highly complex design and constantly improving engineering. Now offers the original RPPM design for higher power lasers. At the same time, the Researchers team is developing a next-generation instrument called Beam Box that will improve RPPM through simple online laser power measurements and extending the detection range to lower power. Another technology developed in early prototypes is Smart Mirror, which will further reduce the size of the meter and provide the ability to detect very small amounts of power. Eventually, it will extend accurate radiation pressure measurements to levels applied by radio waves or microwave beams that currently severely lack the ability to measure accurately.

Higher laser power is usually measured by aiming the beam at a certain amount of circulating water and detecting a temperature increase. The tanks involved can be large and portability is an issue. Calibration usually requires laser transmission to a standard laboratory. Another unfortunate drawback: the detection instrument is in danger of being damaged by the laser beam it is supposed to measure. Various radiation pressure models can eliminate these problems and enable accurate power measurements at the user’s site.

Post time: Jul-31-2024