Integration of camera and LiDAR for precise detection

Recently, a Japanese scientific team has developed a unique camera LiDAR fusion sensor, which is the world’s first LiDAR that aligns the optical axes of a camera and LiDAR into a single sensor. This unique design enables real-time collection of parallax free overlay data. Its laser irradiation density is higher than all laser radar sensors in the world, enabling long-distance and high-precision object detection.

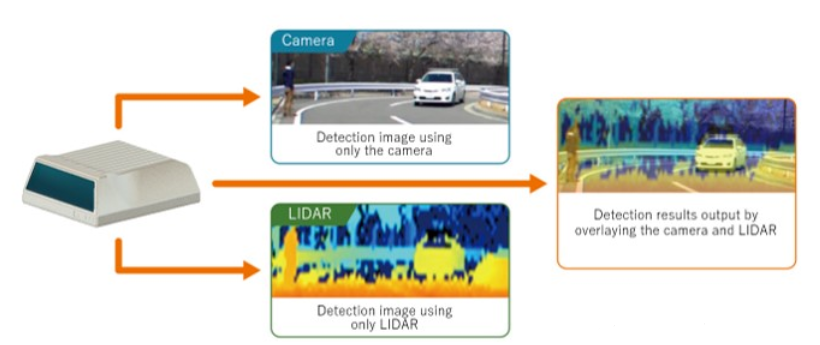

Usually, LiDAR is used in conjunction with cameras to more accurately identify objects, but there is a disparity in the data obtained by different units, resulting in calibration delays between sensors. The newly developed fusion sensor integrates the camera and high-resolution LiDAR into one unit, achieving real-time data integration without parallax, ensuring efficient and accurate results.

The integration of camera and LiDAR achieves precise object recognition. The team utilizes unique optical design technology to integrate the camera and LiDAR into a unit with aligned optical axis, enabling real-time integration of camera image data and LiDAR distance data, achieving the most advanced object recognition to date. The laser radar with ultra-high resolution combined with the world’s highest laser emission density fusion sensor has increased the density of the emitted laser beam, which can identify small obstacles at long distances, thereby improving resolution and accuracy. His innovative sensor has an irradiation density of 0.045 degrees and utilizes proprietary laser scanning unit technology from multifunctional printers (MFPs) and printers to detect falling objects up to 30 centimeters at a distance of 100 meters.

High durability and proprietary MEMS mirror laser radar require MEMS mirrors or motors to irradiate the laser onto a wide and high-density area. However, the resolution of MEMS mirrors is usually low, and the motor often wears out quickly. This new integrated sensor provides higher resolution than motor based systems and greater durability than traditional MEMS mirrors. Scientists use advanced manufacturing, ceramic packaging technology and high-resolution laser scanning technology to develop proprietary MEMS mirrors to support high-precision sensing in various industries such as autonomous vehicle, ships, heavy machinery, etc.

FIG1:Image detected by camera LiDAR fusion sensor

Post time: Feb-10-2025